Our Quality Assurance System guarantees scrupulous observation of all design, construction and testing procedures.

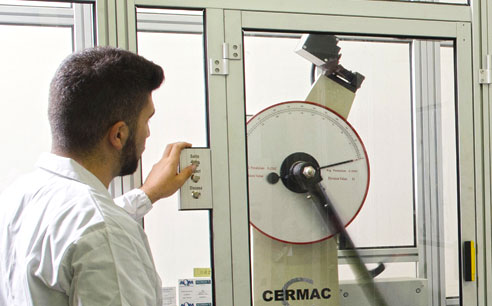

Our laboratories have most modern equipment , allowing us to carry out all types of quality control and testing, including mechanical tests, chemical analysis, micrographic examination, destructive and non-destructive tests, comparative checks on raw materials and finished products in accordance with International Standars.

OMS Saleri carries out all types of testing, including: non-destructive examination (magnetic particle, radiographic, roughness, dye penetrant and ultrasonic tests) and corrosion testing: